In a nutshell it is unpredictable unless you have your people there, holding others at the Chinese equivalent of a gunpoint (maybe a gunpoint?).

One way to decrease those risks is to work with the same vendor and build mutual trust, educate them on how to avoid mistakes etc.

However even then you are not guaranteed.

We are working with the same vendor for many years now and have been together through a lot already.

Which did not prevent us from receiving a batch of STK795-821 ICs that had a problem we have never seen before: a shortage between the Vs input power (200V) and the IPM control logic driving power 15V (often labeled Vg).

Here is what I mean:

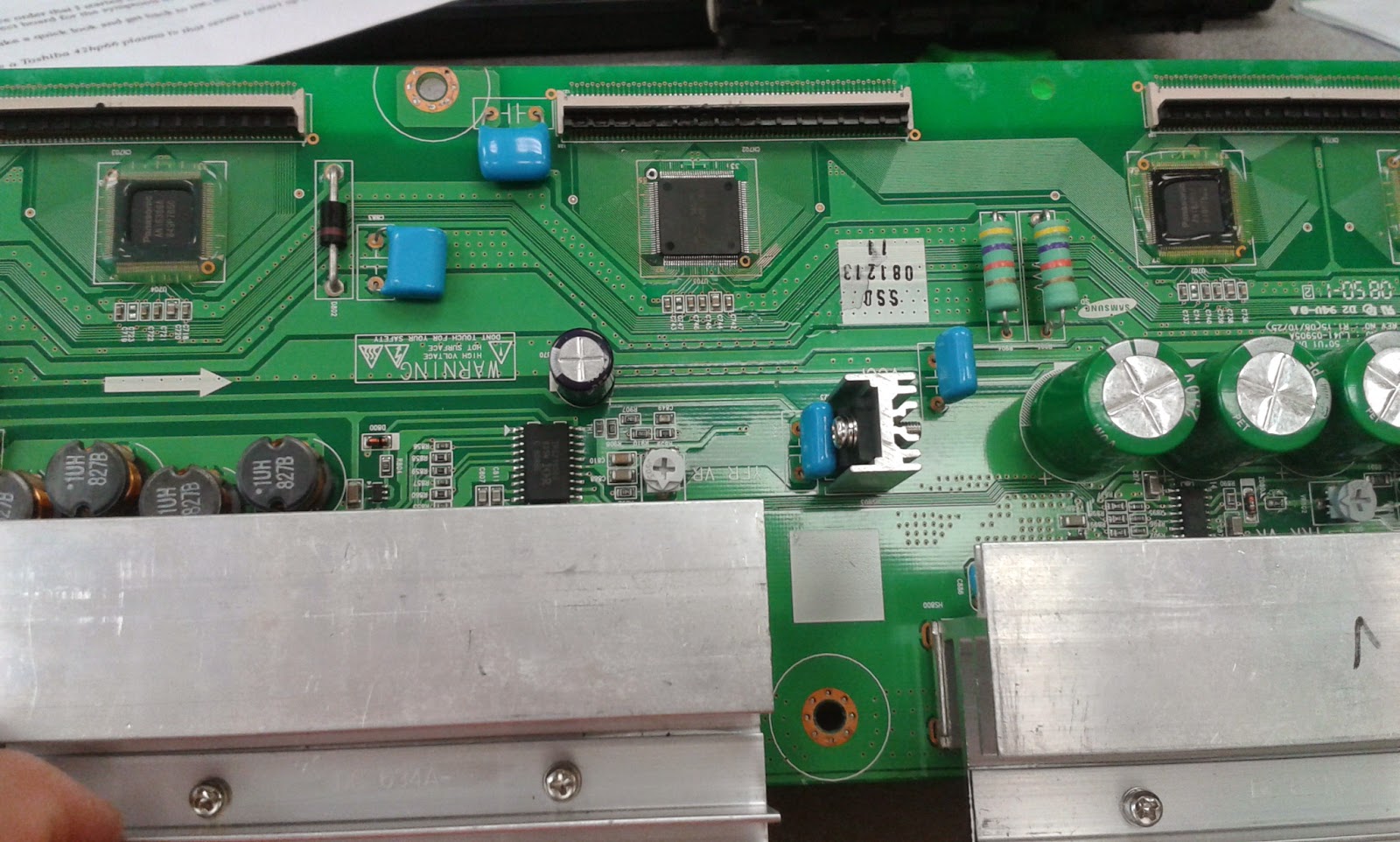

This is a picture of the bottom of a YSUS board 6871QYH053B which uses STK795-820 or STK795-821 or YPPD-J018C or YPPD-J018E etc.

I am enclosing that picture here so that you can easily see the groups of pins on the IPM.

We've sold over a 1000 ICs and repair kits and we've fixed probably just as much internally and I can easily say that 99% of all failures manifest themselves as one of the following:

- Short between Vs and GND pins

- Short between Vs and SUS_OUT

- Short between GND and SUS_OUT (I am actually not sure about this one, but it's worth checking)

- Diode effect (one-direction resistance) between VER1/VER2 (they're shorted out on the PCB) and ER_DOWN_OUT; normally there should be infinite resistance in both directions, but an internally shorted FET would leave a diode in the circuit between the two.

The effect would be flashing on the screen.

Until last week when we received, in a box from a large batch of ICs, the following:

We've labeled the pins for you. There were 28 ICs with Vg shorted to Vs!

Unaware of that, we just processed normally a repair service for a board and proceeded to testing the result.

Bang, bang,

went PCBs,

and I assure you

bang, bang,

burned the TV...

Wait a minute, what you sold me there?

Wait a minute, that's a freakin' nightmare...

Bang, bang..

OK, enough TV pop folklore :-)

First, you should remember that resistance between Vg and Vs should always be infinite as shown below, only in both directions:

Second, you can bet that once you solder an IC that has a shorted Vg to Vs and test that in a live set, you will have A WHOLE LOT MORE damage than you originally started with.

For a starter, the ZSUS board's IC will also fail since it uses the same +15V that are produced on the YSUS board and dispatched, through the plasma logic board, to the ZSUS; but everything , or nearly everything, that is on the YSUS and feeds from the +15V will likely also be damaged.

This case is a great illustration of a few important takeaways:

1) You better know what you're soldering on a board; it won't hurt you if you test everything that you know tends to fail.

2) You are definitely better off buying ICs from someone who uses them versus someone who just imports them and sells them; you are not guaranteed unless said someone tells you they've tested the IPMs and they are honest, but you are , by all means, better protected if someone is working with the same material that you're going to be using.

We can't say with 100% certainty haven't sold a single IC of those to a customer, but chances are we didn't because we usually start using internally products from new shipments while continuing to sell the products from previous shipments - exactly for the sake of being first line of protection for customers.

Of course that is still not a 100% certain because , like in this case, only one and a half box out of twenty happened to be bad.

3) You can make a mistake even when working with a trusted vendor; that is because they themselves work with local vendors sometimes; of course that also means you would be better off being a first tier, but in many cases that is simply impossible.

Yet working with a trust vendor helps a lot resolve the problem and they would often times walk an extra mile to cushion any and all losses.

4) Maybe a bit strange for some, but for me this is a great illustration of why we should NOT warrant ICs once they are on a board. You see, a number of things can be bad on a board or in an IPM; to date I see some of my own technicians occasionally short two pins when soldering. Not those particular two, because they are quite apart, but certain other two are just sufficient.

The result would still be a failed board, sometimes filed buffer etc.

Any mistake - be it internal or induced - can cause a lot of damage.

A responsibility line must be drawn somewhere and I do not see a better place of running heavy current through the IPM.

We can't easily catch this particular case and the next best is just soldering the IPM on a board.

I'll finish this article with another two pictures for a different board we received from our vendor and the problem with it. The board was returned by a customer who claimed there were was a horizontal bar of about 1/8th of an inch that was dark no matter how may times he adjusted the plasma display ribbons to the connectors:

This is a Samsung Y-Main board LJ92-01601A used in Samsung PN50B450 and others.

It has an embedded YSUS buffer.

And this is what we found out upon careful inspection:

There was simply a cut through the PCB that has disconnected 4 tracks. This picture is made after we've removed the silicone, cleared the tracks and prepared them for connection.

The IC did NOT seem to have been reworked, but I can not see another explanation of how this could have happened.

Good luck in your own repairs!